Производство синтетического сапфира

ЗАО «Ростокс-Н» – ведущий производитель синтетического сапфира в России, качество изделий которого подтверждено отечественными и международными сертификатами

Гарантия высокого качества и отсутствия брака – заказчик получает продукцию, прошедшую строгий предпродажный контроль и в обеспечивающей сохранность упаковке

Закажите просчет стоимости у специалиста – наши цены ниже, чем у конкурентов, оставьте заявку на сайте и получите ответ в течение 24 часов с учетом индивидуальных особенностей заказа

ЗАО «Ростокс-Н» – научно-производственная компания международного уровня, работающая с 1993 года. Сегодня мы поставляем синтетический сапфир и оборудование для выращивания монокристаллов в 25 стран по всему миру.

50 высококвалифицированных специалистов в области роста и обработки кристаллов занимаются производством синтетического сапфира: от выращивания кристаллов до финишной обработки. Мы - профессионалы во всем, что делаем!

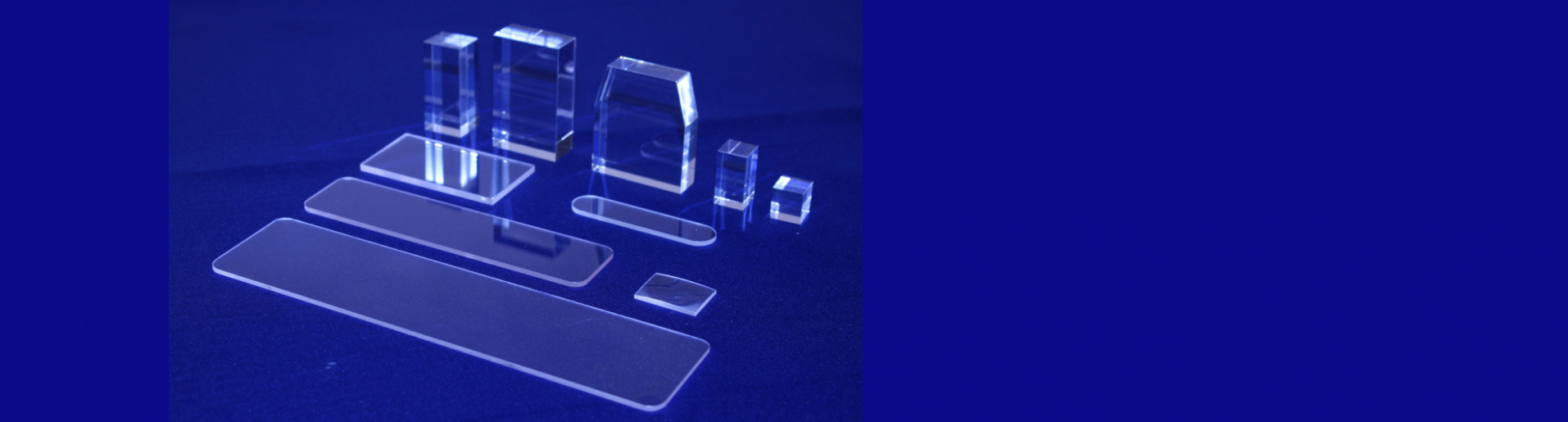

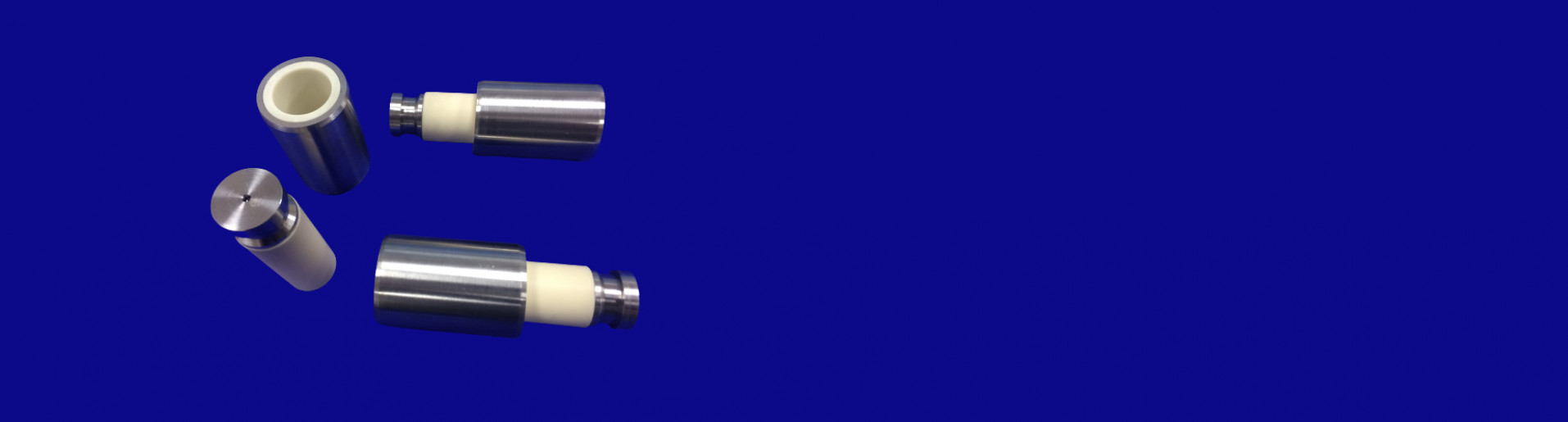

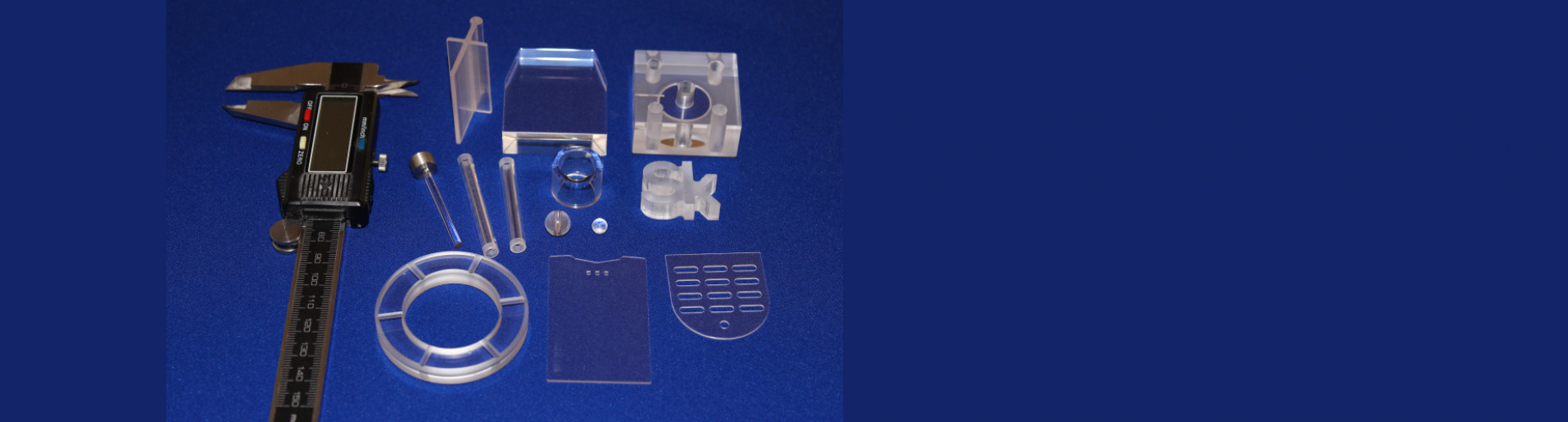

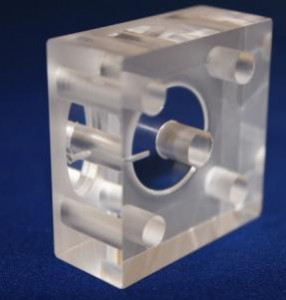

Синтетический сапфир от производителя

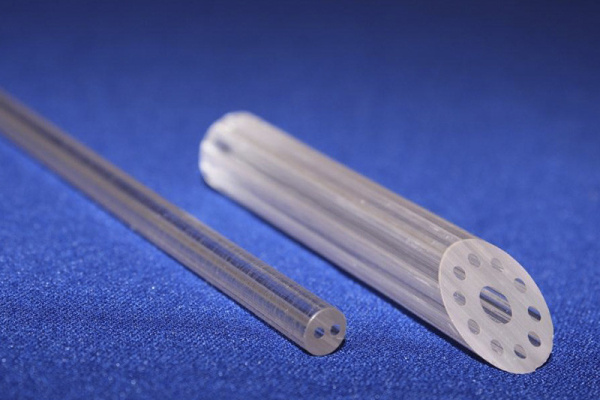

В сфере производства синтетического сапфира наша компания по праву является одним из отечественных и мировых лидеров. Мы выращиваем кристаллы сапфира и изготавливаем из них широкую номенклатуру изделий, в том числе по индивидуальному заказу. У нас вы также можете заказать оборудование для выращивания кристаллов в вашей собственной лаборатории.

Цены на синтетический сапфир

Приобретая лейкосапфир, сапфировые трубки и другие изделия из нашего каталога, вы можете быть уверены в доступных расценках. Мы автоматизировали и оптимизировали свое производство, чтобы на выходе получать качественный сапфир или изделия из него с максимальной выгодой для своих клиентов. Получить прайс-лист на почту вы можете, оставив заявку на нашем сайте или по контактному телефону +7 (496) 527 35 91.

Как купить изделия из сапфира?

Купить искусственный сапфир у производителя ЗАО «Ростокс-Н» можно в любом объеме в срок от 1 дня. Сделать это легко одним из 3 способов:

- Заполнить заявку на сайте.

- Написать нам на электронную почту info@rostox-n.ru.

- Позвонить по телефону +7 (496) 527 35 91.

Наше производство находится в Московской области, в наукограде Черноголовка и поставляет продукцию по всему миру. Мы обеспечим вас лейкосапфиром высокого структурного совершенства!

Остались вопросы?

Получите консультацию у наших менеджеровСвяжитесь с нами

+7 (496) 527 35 91

+7 (496) 527 35 95

+7 (496) 527 35 96

Адрес: 142432, Московская область,

г. Черноголовка, проспект академика Семенова, д. 9.

Email: rostox-n@yandex.ru, info@rostox-n.ru

Режим работы: пн-пт с 08:00 до 17:00